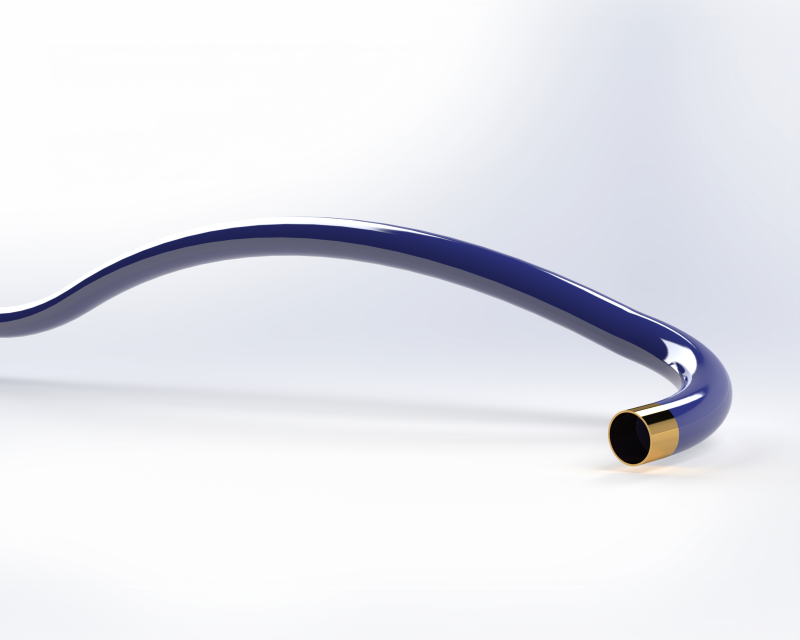

Catheter Design, Prototyping, and Manufacturing

Your Partner in Custom Catheter Design & Manufacturing

A Vital Partner in Your Product Journey

Solving the Toughest Challenges in Catheter Design

Real-world catheter challenges do not get solved in a slide deck. They get solved on the whiteboard, at the bench, and in the lab.

At VitalPath, we partner directly with engineering teams to work through the iterative and rewarding process of catheter development. Whether it’s improving torque response, solving bond joint failures, or eliminating flash at the distal tip, we’re hands-on from day one.

This is a behind-the-scenes look at how our engineers collaborate, troubleshoot, and iterate quickly to help move your design forward, faster.

Because when you’re building something complex, you need a partner who’s just as invested in the details as you are.

Fully Customizable

Product Development Process

We fully customize our product development process based on the specific needs of your project. Where others may be bogged down by overly complex and rigid processes, the VitalPath team understands the need to be flexible and responsive to keep timelines on track to meet key milestones.

We use a responsive, problem-solving approach to

Rapid Prototyping

Our expertise, capabilities, and streamlined process allow us to quickly build complex catheter and delivery solutions.

- Custom prototypes—FAST

- Rapid design, build, and test prototype cycles

- Typically, 2–3 runs of 10–20 samples each are needed before design freeze

- In-house component capabilities enable quick turnaround

Our Engineers will act as

An Extension of Your Team

Our experienced engineers have the deep technical knowledge needed to take your challenging concept and deliver a manufacturable device.

We collaborate with you to:

- Improve your design to meet manufacturing capabilities

- Verify manufacturing processes are capable

- Validate repeatability and reliability

- Execute per our mature ISO 13485 quality systems

We offer a wide range of secondary operations in house, saving time and streamlining your supply chain.

Our custom, complex component capabilities include:

- Complex device assemblies

- Braiding & coiling

- Curved & steerable catheters

- Complex extrusions

- Laser welding and cutting

- Wire forming & ablation

- Nitinol forming

Support through ramp

Flexible, high-mix manufacturing

We can handle all your catheter manufacturing needs, from pilot production through volume manufacturing.

Specializing in high-mix manufacturing, we have the flexible people, processes, and systems to meet the challenges of manufacturing scale-up.

Benefits of high-mix manufacturing include:

- Accommodates design changes typical with launching new technology

- Lot-release quality systems speed time to clinical trials and market launch

- Supports customer during growth, as important new technologies may spend years in low-volume production

- Provides a manufacturing pathway supporting all phases of growth

Once we build your shaft or delivery system to your specifications and it performs as intended, we can manufacture your finished device in our FDA-registered facility. Or, we can hand it back to you for the finishing touches, whether that’s loading a stent or adding a handle.

Our production manufacturing services include:

- Process development

- Verification

- Validation

- Scalable QA systems

Contract Manufacturing

Volume Manufacturing and Finished Device Assembly

ISO 13485:2016 Certified

FDA Registered

300+ Employees

3 Minneapolis Locations

ISO 7 & 8 Cleanrooms

Let's Partner

We cannot wait to collaborate with you at our dedicated design center for real time feedback during rapid prototyping, design iterations, testing, and more!