Your Most Challenging Requirements, Met

We do what others can’t. We push the boundaries in building complex catheters, components, and subassemblies to meet your most challenging requirements. It’s our core expertise.

Assembly

Our assembly operations include:

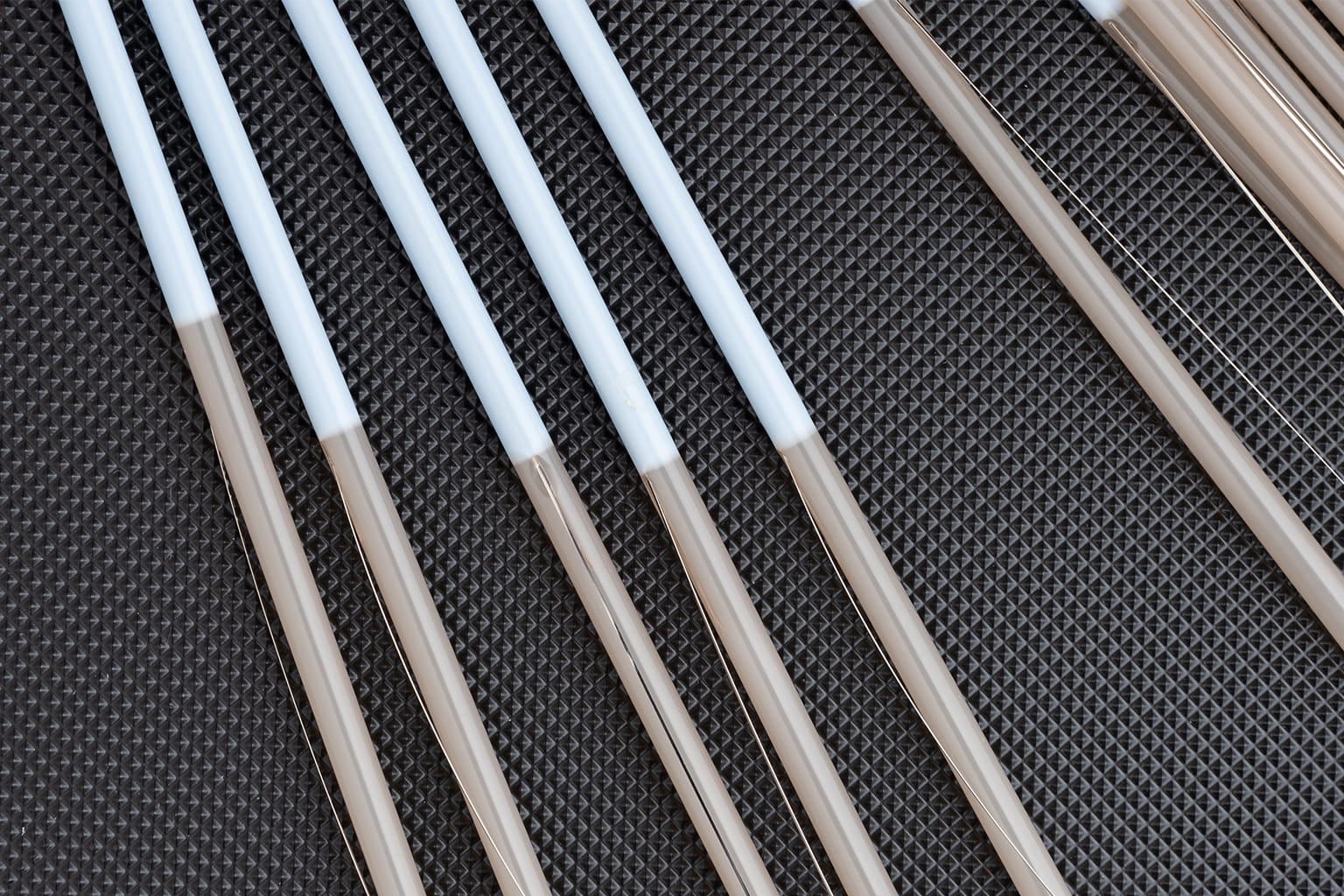

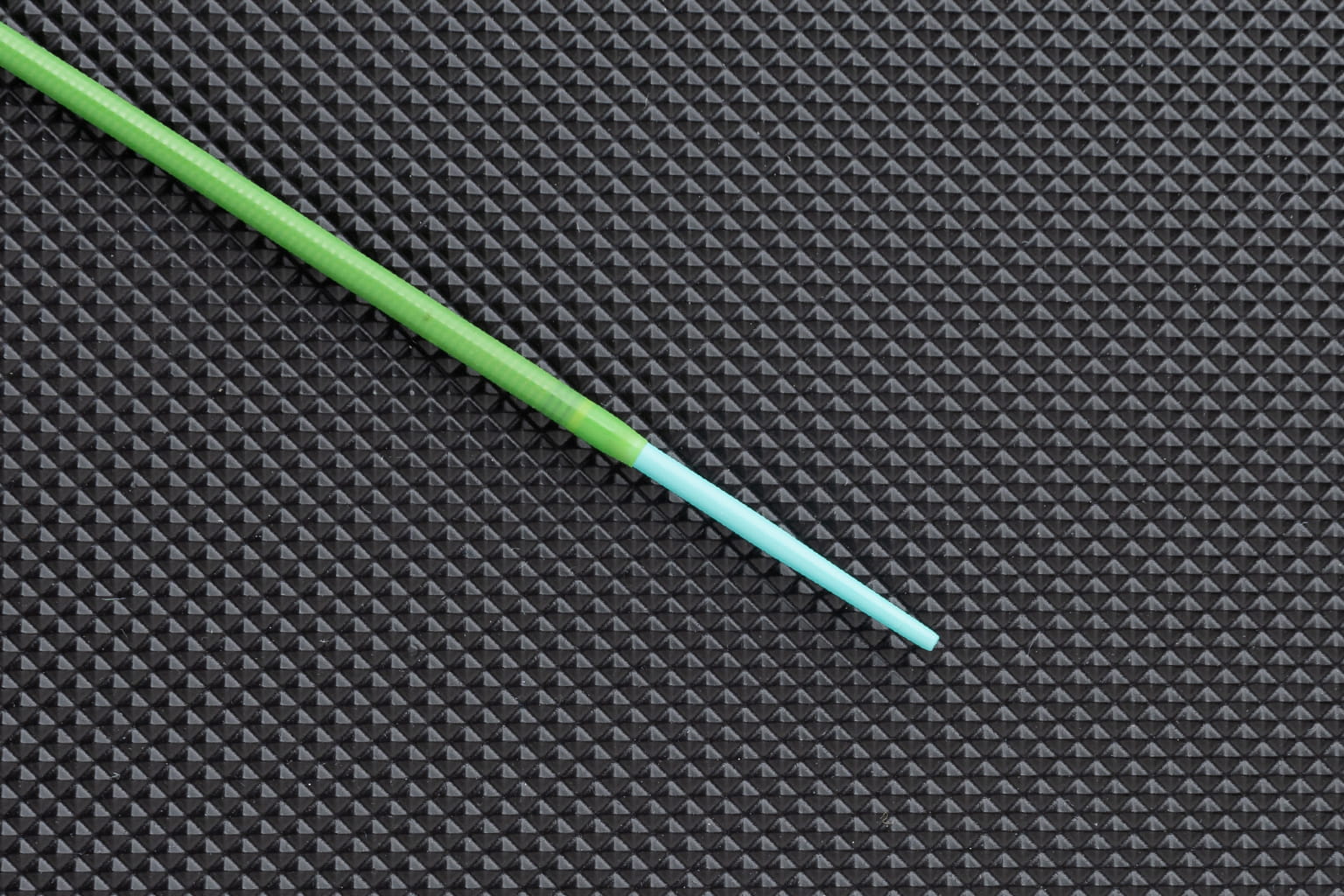

Extrusions

Extrusion capabilities for:

- Steerable/deflectable catheters

- Micro, guiding, EP, balloon, and delivery catheters

- Multiple durometers

- Multiple braided layers for torque and kink resistances

- Multiple-lumen braided tubing

Sizing

- 2 Fr (.026”/.33 mm)–28 Fr (.368”/9.33 mm)

- Thin-wall construction (as thin as .002“)

Materials

- Pebax®

- Vestamid®, Grilamid®, nylon 12

- Polyurethane

Customization

- Colorants

- Fillers

- Additives

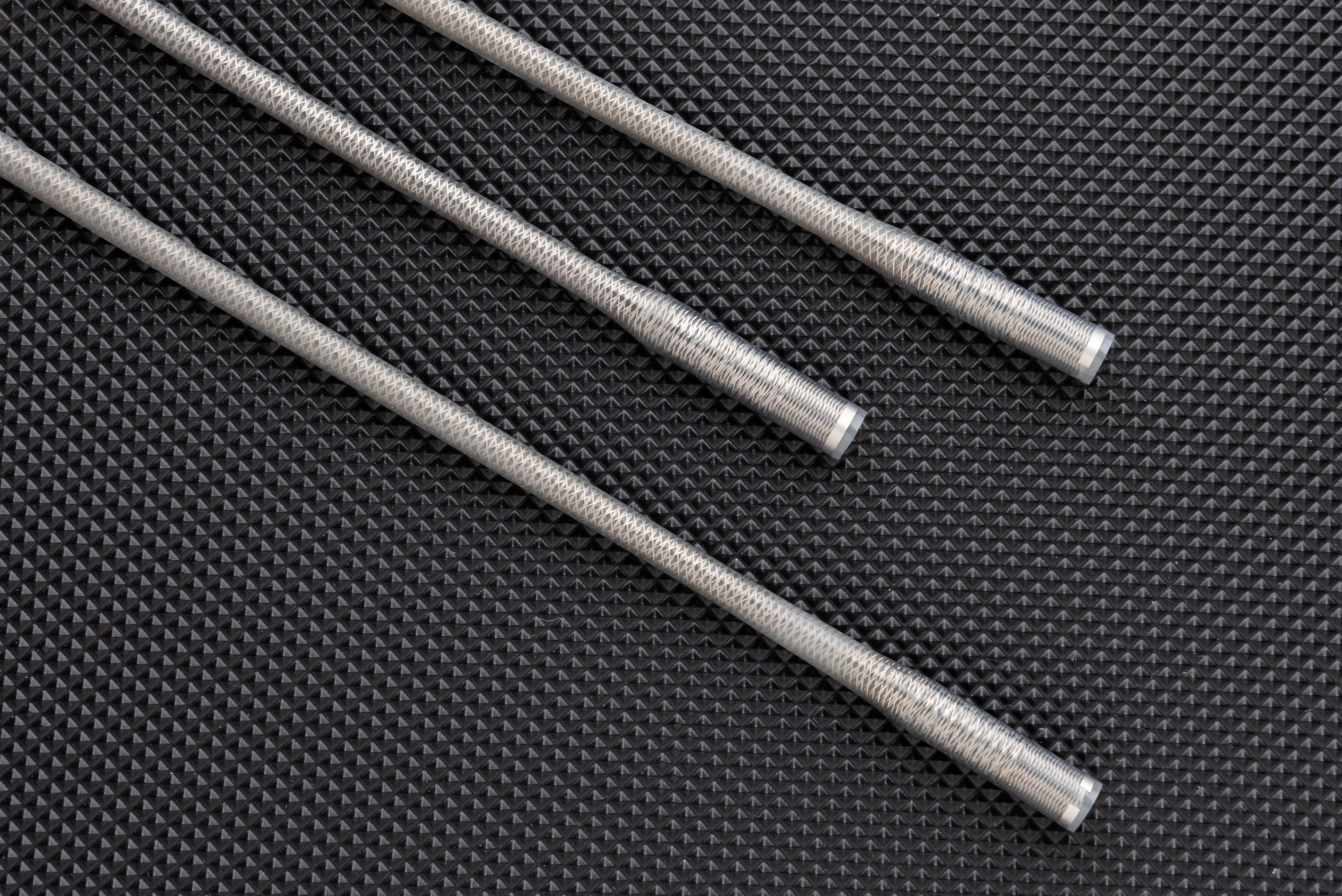

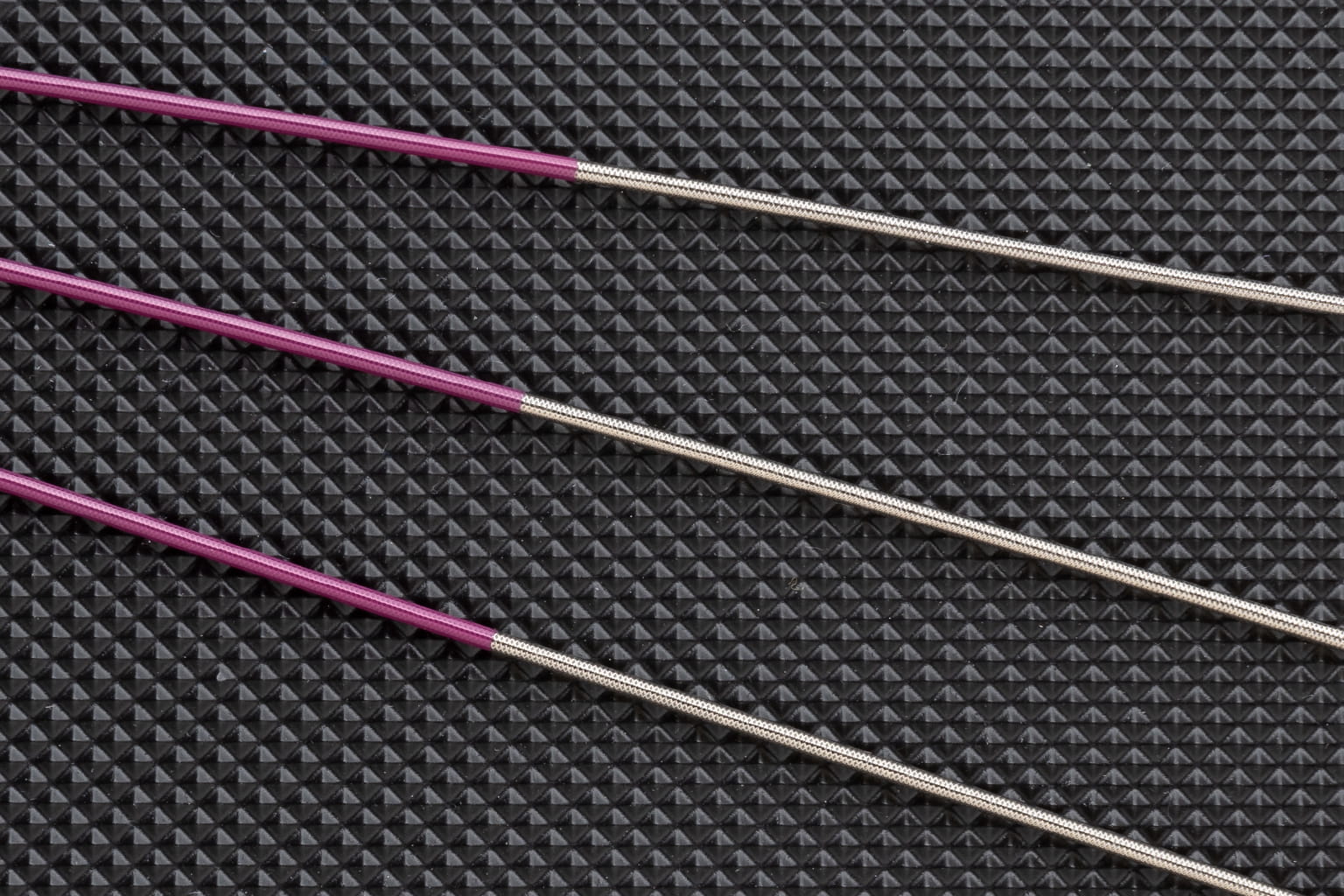

Braiding

- Continuous and multiple-segment capabilities

- Flat & round

- Tensile range: 150 kpsi–350 kpsi

- Braiding patterns

- Variable PPI braid segments

- Regular pattern (1 wire over 2 wires/under 2 wires)

- Diamond braid pattern, full load (2 wires under 2 wires/over 2 wires)

- Diamond braid pattern, half load (1 wire under 1 wire/over 1 wire)

Coiling

- Tensile range: 150 kpsi–350 kpsi

- Continuous pitch/gap

- Multiple pitch/gap

- Tapered ID/OD transitions

Additional assembly operations

- Reflow

- Tip forming

- Flaring

- Necking

- Skiving

- Swaging

- Adhesive bonding

Metals

Our metal capabilities include:

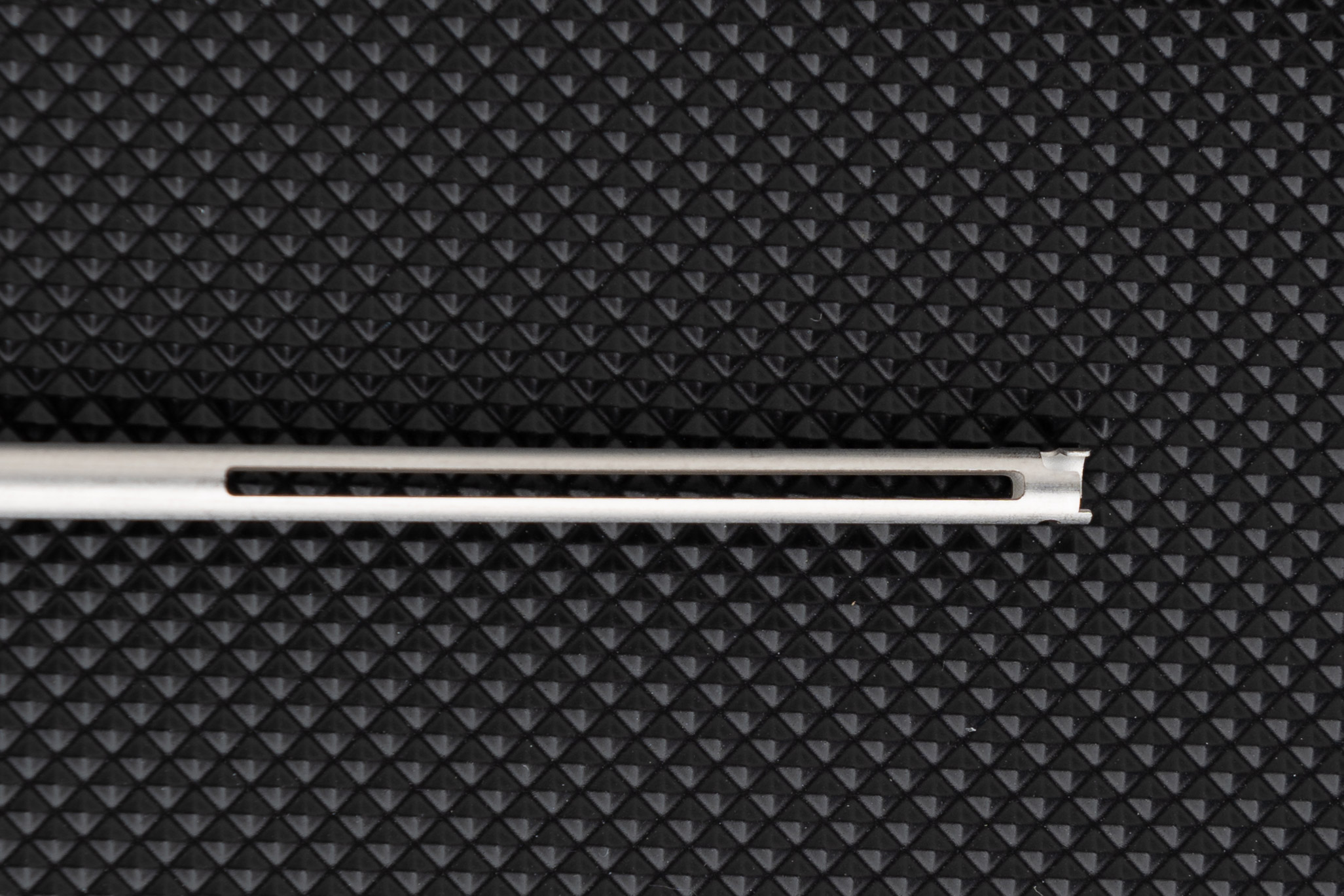

Laser cutting

Metal tube cutting

- Flexible hypotubes

- Stents

- Baskets

- From very small parts to very long parts

- Materials:

- Stainless steel

- Nitinol

- MP35N

- Titanium

Polymer tube cutting

- Clear and opaque polymer materials including:

- Pebax®

- Polyurethane

- Polyimide

- PEEK

Laser welding

- Pull wires

- Fine wires

- Capped needles

- Variety of metals & polymers

- Expertise in welding dissimilar material

Laser ablation

- Very small wire ablation (diameter as small as .0015”)

- High-speed precision removal of polymer coating

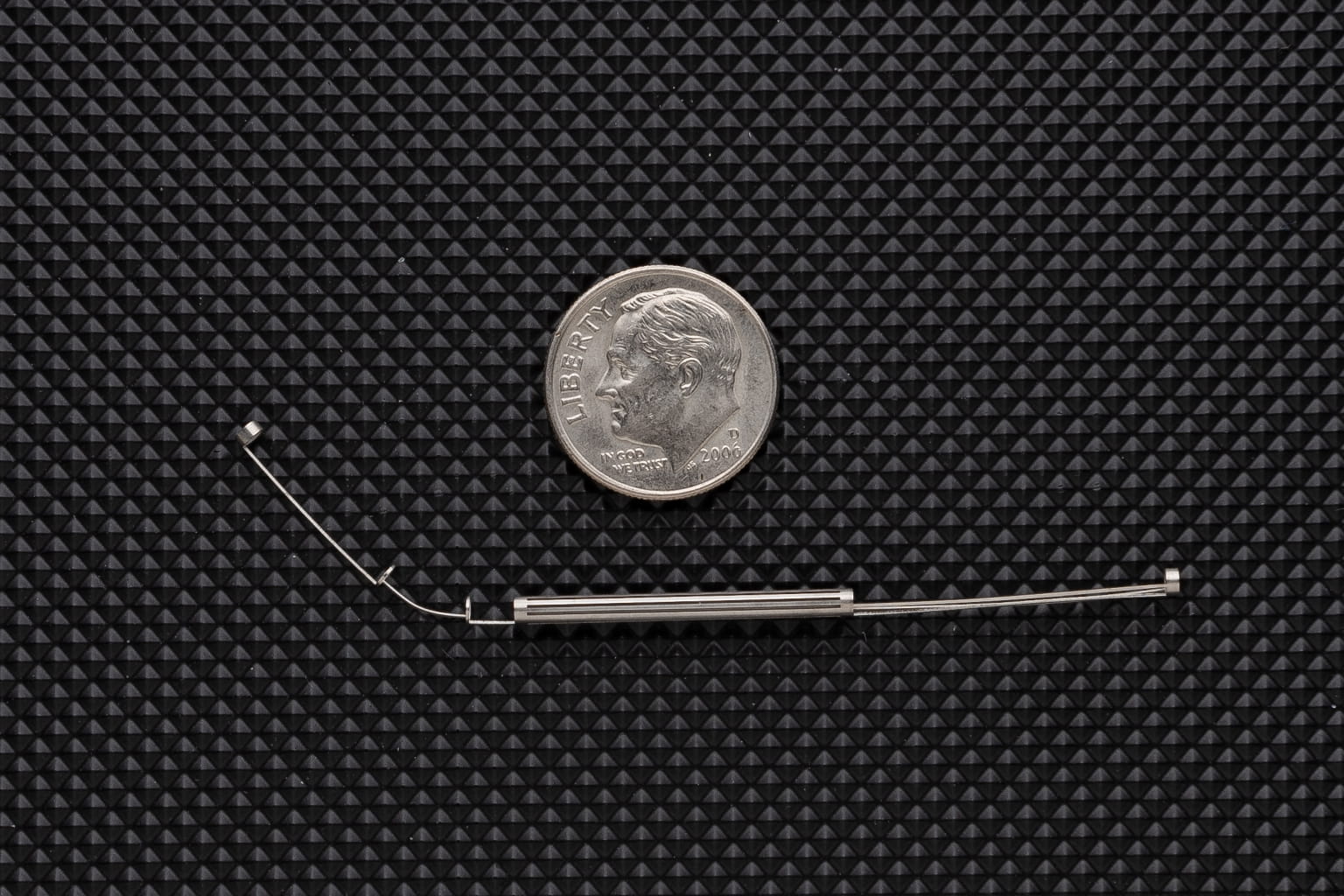

Forming & bending

- Wire forming

- Wire sizes from .008”–.063”

- Formed stylets

- Coils

- Springs

- Complex wire forming

Additional metals capabilities

- Machining

- Soldering

- Bonding

Finishing

Our finishing capabilities include:

Finishing

- Laser marking

- Laser drilling, skiving, and machining

- Tipping, flaring, and swaging

- Pad printing

- Electropolishing

- PTFE lubricious coating

GOT A COMPLEX CATHETER DESIGN? BRING IT ON.

Looking for a responsive, reliable partner to help you get your complex catheter or catheter components to market fast?

We’d love to hear about your project.

Complex Catheter Solutions

Whether you need in-plane deflection or multiplane curvature, our proprietary process provides the deflection where you need it and won’t steer you in the wrong direction.

Fixed-shape catheter

- Multiplane curvature

- No relaxation of curve at body temperature

- Tight radius

- Thin walls

- Cost efficient; eliminates need for expensive nitinol solutions

- High torque transmission

- Kink resistant

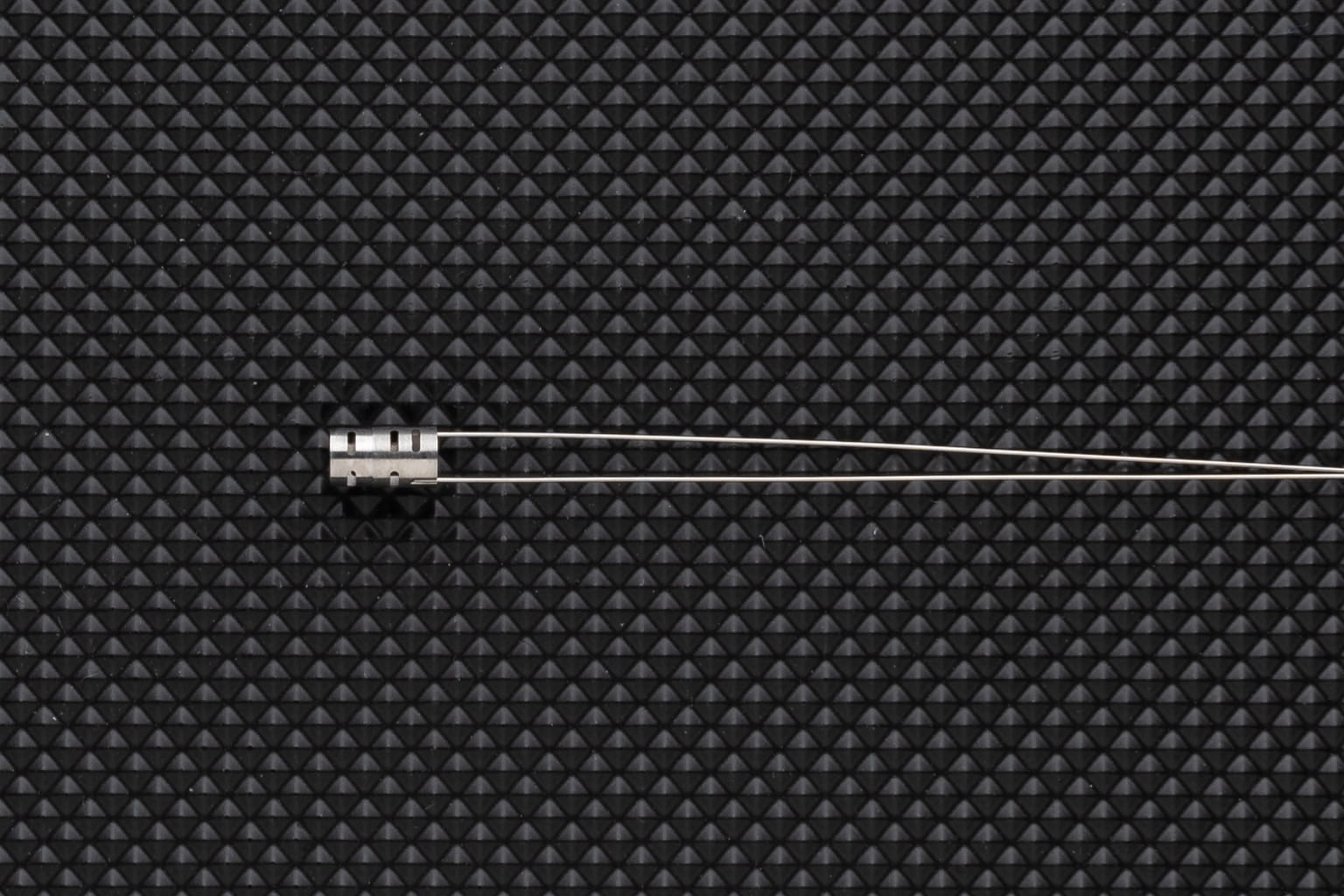

Steerable catheter

- Multiplane steerability

- Complex pull-wire designs

- High torque transmission

- Kink resistant