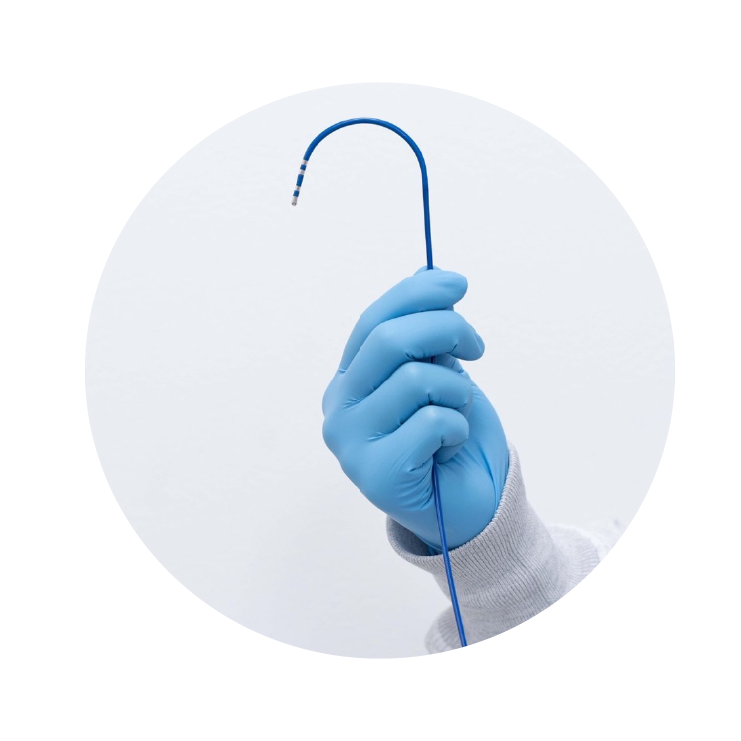

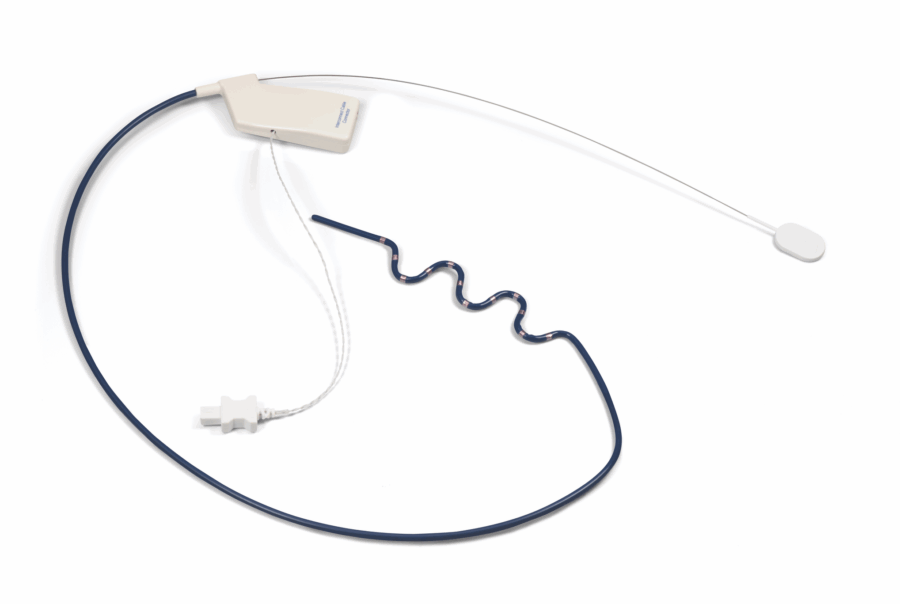

We partner with OEMs to design, develop, and manufacture precision components, reinforced sheaths and shafts, and complete catheter solutions for electrophysiology procedures that utilize radio frequency (RF), cryoablation, pulsed field ablation (PFA) or any combination of technologies.

OEM Partnerships for Complex Electrophysiology Devices

At VitalPath, we partner with you and act as an extension of your engineering team in building complex catheters, components, and subassemblies to meet your most challenging requirements from start to finish.

Technologies We Support

Download our Capability CardCatheters and Components for the Electrophysiology Market

Our OEM partners leverage our comprehensive breadth of in-house precision component and complex catheter development and manufacturing expertise to bring their most challenging EP catheters to life, faster.

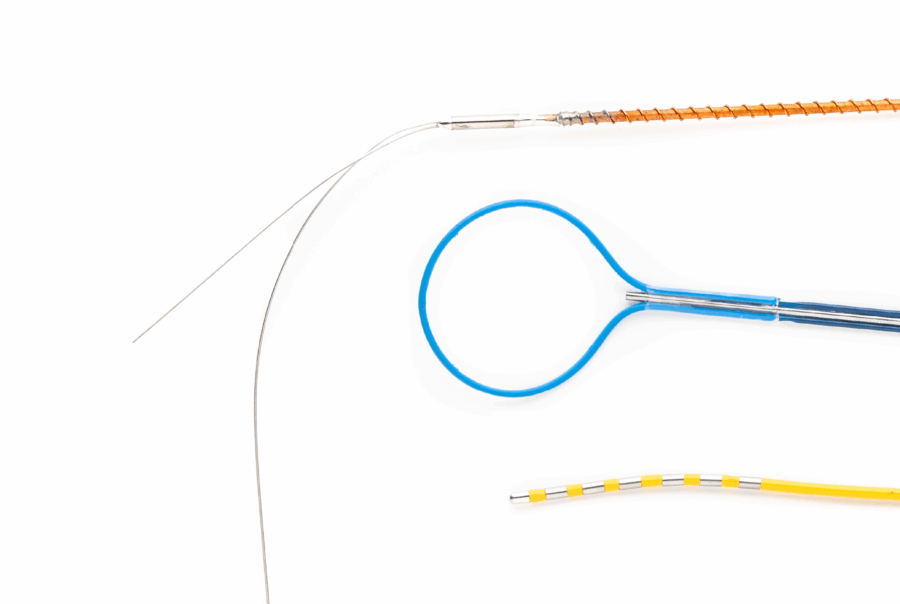

Electrophysiology Catheter Types

- Ablation Catheters

- Balloon Catheters

- Energy-Delivery Catheters

- Steerable Introducer Sheaths

- Transseptal Sheaths

- Temperature Sensing Catheters

- ICE Catheters

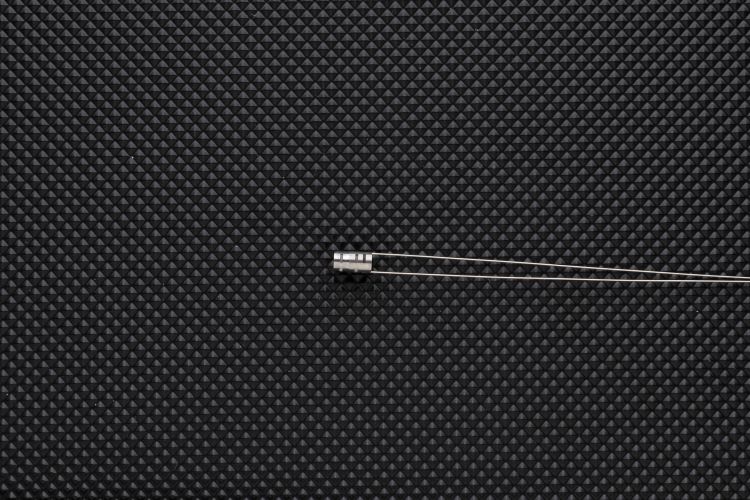

Electrode Cutting and Welding

- In-House Electrode Cutting

- Custom Shapes

- Resistance Welding

Pull Wire Assemblies

- Wire Cut to Length

- Laser Cutting Hypotubes

- Laser Welding and Braising

- Traditional Metal and Kevlar Pull Wires

- 1 to 4 Pull Wires

Catheter Tips

- Sensor Integration

- Wire Termination

- Marker Bands

- Nitinol Component Integration

- Balloon Bonding and Assembly

- Tip Profiling

- Multiplanar and Multidirectional Steerable Tips

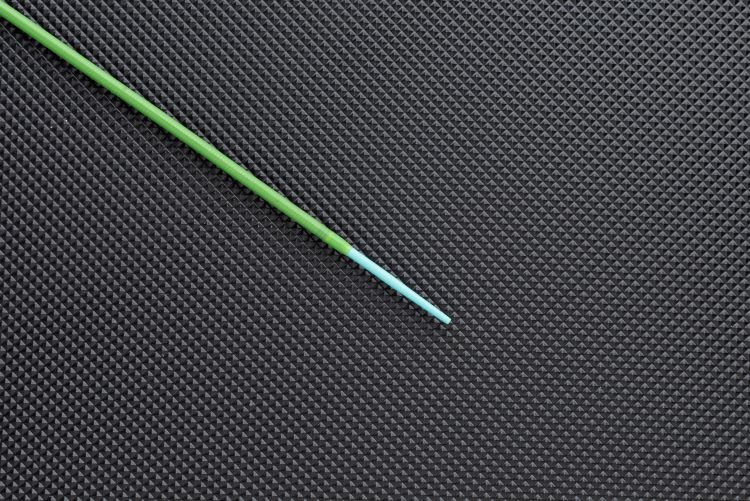

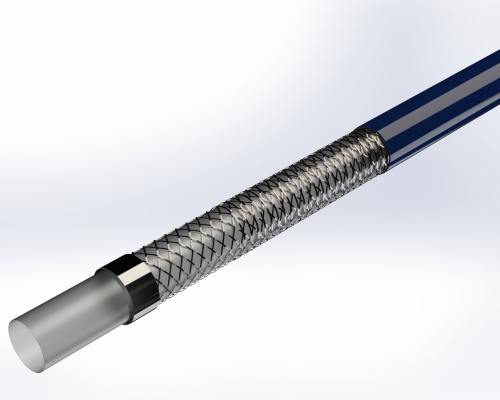

Reinforced Catheter Shafts

- Braid and Coil Reinforcement

- Multi-lumen Shafts

- Laser Cut shafts

- Pull Wire Assemblies

- Multi-Durometer Extrusions

- Multi-Layer Extrusions

Finishing and Sub-Assembly

- Overmolding

- Bonding

- Hole Drilling

- Laser Marking

- Strain Relief

- Final Packaging

A Vital Partner in Your Product Journey

Custom Electrodes

In this short video clip, Tom Brinkman, Sr. R&D Engineer and laser processing specialist from VitalPath, discusses custom laser cutting and resistance welding of electrodes. Kate Soojian, Director of R&D adds to the discussion with some key design considerations for integrating the electrodes into the final catheter for optimal performance.

Find your next partner for your complex catheter design.

Looking for a responsive, reliable partner to help you get your complex catheter or catheter components to market fast? We’d love to hear about your project.